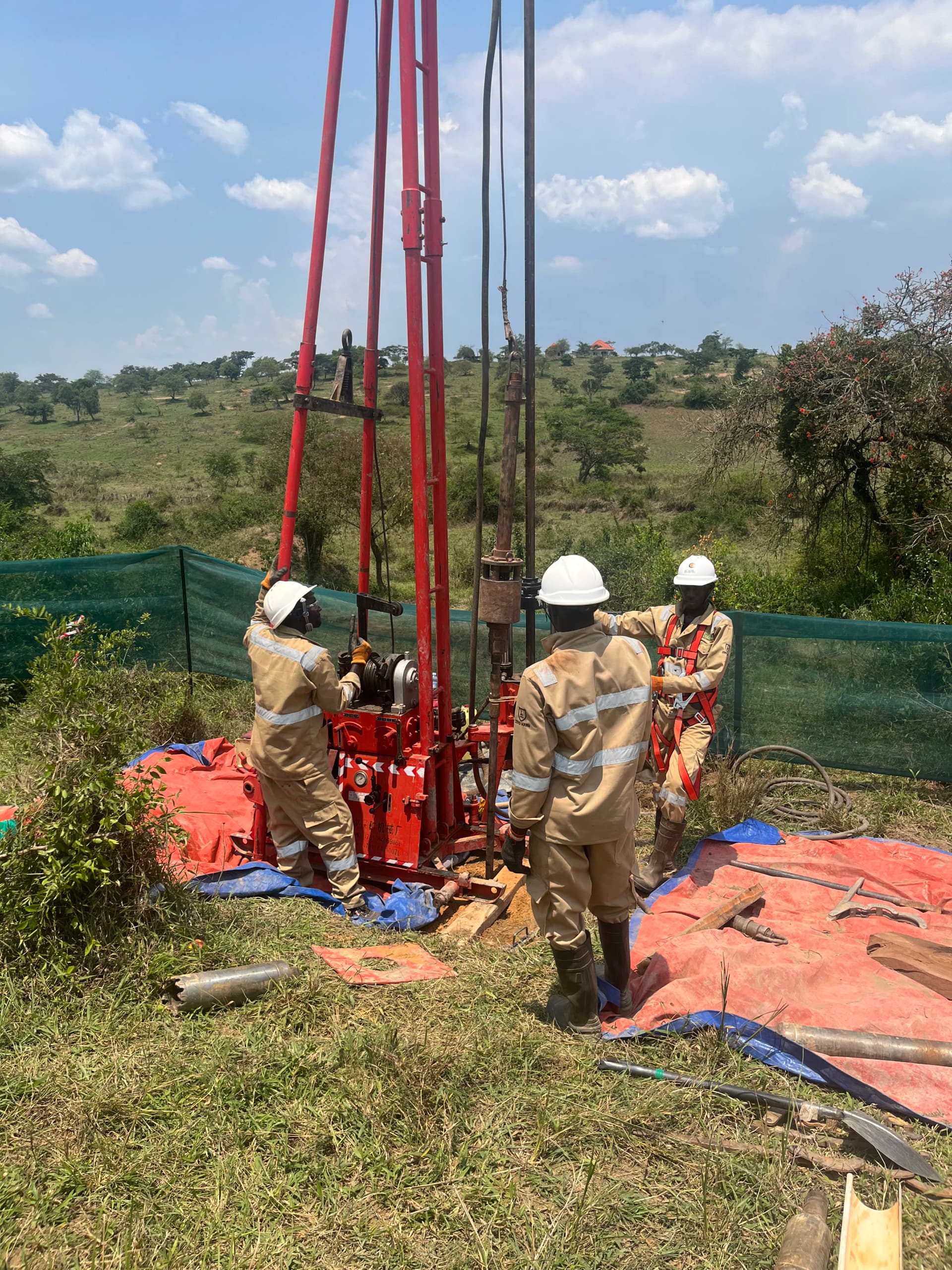

Geotechnical Investigations Along the EACOP Pipeline (MLBV/LLHT) Substations

The East African Crude Oil Pipeline (EACOP) is a major infrastructure project designed to transport crude oil from the oil fields in Uganda to the port of Tanga in Tanzania, where it will be exported to international markets. The Uganda section of the pipeline is 296km cutting through 28 substations, 3 town councils and 171 villages in 10 districts of Hoima, Kikuube, Kakumiro, Kyankwanzi, Mubende, Gomba, Sembabule, Lwengo, Rakai, and kyotera.

Challenge

The EACOP project required a detailed geotechnical investigation across multiple sites located approximately 200 km apart over a 1,000 km distance. The terrain along the proposed pipeline presented various challenges, including varying soil conditions, bedrock depths, and remote site access. The investigation called for accurate subsoil profiling to ensure the pipeline's long-term stability and safe construction, with the need for boreholes and rigorous environmental standards. Additionally, strict timelines and safety standards had to be met while working in remote areas that were difficult to access with heavy drilling equipment.

Solution

Our team deployed advanced geotechnical techniques tailored to the specific challenges of each site. With highly skilled personnel and state-of-the-art drilling rigs, we used rotary core drilling method for soil and rock recovery ensuring retrieval of sufficient core samples and accurate profile logging. We performed Standard Penetration Tests (SPT) with Shelby Tube (ST) sampling and conducted permeability test in the boreholes across various sites. Test pits of 1.5 meters depth were excavated and Thermal Conductivity Tests (TCT) was carried out. In addition, PANDA Tests and Electrical Resistivity Tests were conducted. All the obtained samples were meticulously logged and stored for laboratory testing. Despite the remote locations, we adhered to the highest safety standards, sustainability and utilized a well-coordinated logistics plan to minimize delays.

Results

The geotechnical investigation is still ongoing and will becompleted on schedule, providing a comprehensive factual report that will include detailed logs of soil and rock conditions, groundwater levels, and environmental assessments. The data will enable the EACOP engineering team to make informed decisions about the design and construction of substations, ensuring the stability of the pipeline. The successful execution of this project will not only meet the technical and environmental requirements but also set a benchmark for safety and efficiency in geotechnical services for large-scale infrastructure projects.

China Petroleum Pipeline Engineering Co. Ltd. (CPP)

CPP has started working with GETLAB since August 2024

http://cpp.cnpc.com.cn/gdjen/PANDA Tests - Lightweight Dynamic Cone Penetrometer (DCP) with variable energy

PANDA® is DCP on steroids. It has so much more capability than a conventional DCP and overcomes the safety issues. We used this portable method for evaluating soil strength

Permeability Tests

Permeability tests for oil pipeline projects are essential to assess how fluids (like water or hydrocarbons) move through the soil or rock in the area. These tests evaluate the ground’s ability to contain or transport fluids, which is critical for ensuring the structural integrity of the pipeline and prevent leaks.

Thermal Conductivity Tests

Test pits were excavated to 1.5m depth to conduct the Thermal Conductivity Test. For a buried pipeline, the thermal conductivity of the surrounding soil is the most important factor determining the overall heat transfer from the pipeline, and plays an important role in assessing the safety and energy consumption of pipeline operation

Electrical Resistivity Tests

Electrical resistivity tests measure the soil’s resistance to electrical current. This is especially important for assessing the risk of corrosion in pipelines, as well as for cathodic protection system design (a method to prevent corrosion).